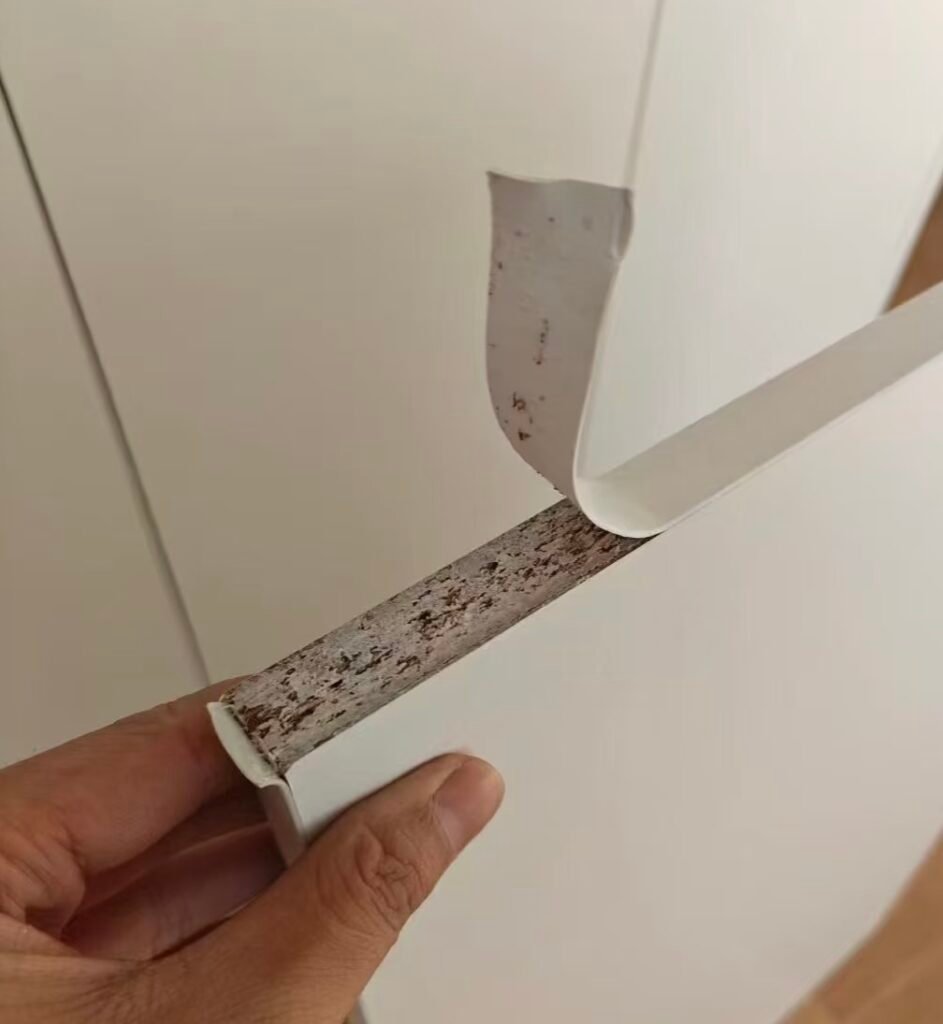

Possible Cause

Hot melt adhesive temperature too low

Insufficient glue application

Insufficient pressure

Board temperature too low

Edge banding temperature too low

Incompatible hot melt adhesive type

Quality issues with the edge banding backing

Solution

Increase hot melt adhesive temperature

Increase glue application

Increase pressure roller pressure

Preheat the board

Preheat the edge banding

Replace with a suitable hot melt adhesive

Check the edge banding backing

Possible Cause

Feed speed too high

Too few trimming knife teeth

Rotational speed too low

Trimming knife head dull

Improper trimming knife head speed

Solution

Reduce feed speed

Use trimming knife heads with more teeth

Increase rotational speed

Replace or sharpen the trimming knife head

Adjust trimming knife head speed, generally 12000-18000 rpm is suitable for counter-milling cutter heads 1

Possible Cause

Excessive glue application

Improper glue roller setting

Hot melt adhesive temperature too low

Feed speed too low

Contact pressure of pressure roller too low

Inappropriate open/curing time of hot melt adhesive (straight line edgebander, glue remains on the board)

Insufficient glue application (straight line edgebander, glue remains on the board, glue roller mesh visible)

Solution

Appropriately reduce glue application

Adjust glue roller position to ensure uniform glue application

Increase hot melt adhesive temperature

Appropriately increase feed speed

Increase contact pressure of pressure roller

Check if the open/curing time of the hot melt adhesive matches the machine speed

Increase glue application

Possible Cause

Feed speed too high

Too few trimming knife teeth

Rotational speed too low

Trimming knife head dull

Improper trimming knife head speed

Solution

Reduce feed speed

Use trimming knife heads with more teeth

Increase rotational speed

Replace or sharpen the trimming knife head

Adjust trimming knife head speed, generally 12000-18000 rpm is suitable for counter-milling cutter heads 1